Polytunnel frames and covers - what are they made of?

It’s a question we get asked a lot. What are our polytunnel frames and covers made from? It’s understandable. A polytunnel can be a significant investment for a hobby gardener, allotment holder or commercial grower. You need to know the product you’re buying is good quality and will last for many years.

British made polytunnels made from high-quality British materials

All our polytunnel kits are made in our Norfolk workshops but we’re often asked what materials we use. The quick answer is that we only use the best British made materials. But let’s look at this in a bit more detail - just so you know exactly what you’re buying when you purchase a commercial grade polytunnel from Direct Plants.

The polytunnel frame

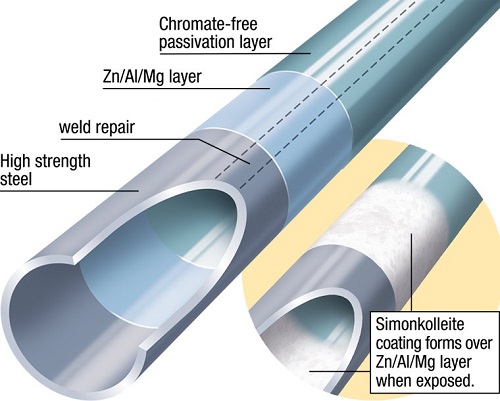

The frame is so important. After all, if it’s made form sub-standard metal it won’t be able to support the cover or withstand high winds and will quickly begin to buckle and rust. Which is why we only use super-strong PolyTube in our kits.

PolyTube is a corrosion-resistant specially coated steel tube. It’s perfect for polytunnels. The warm, sometimes very hot and humid, environment in a polytunnel makes ordinary steel tubing very susceptible to rust and will quickly weaken the structure.

But PolyTube has around 20 times the corrosion resistance compared to the widely used & known Z35 pre Galv galvanised tubing. It is also far stronger and long-lasting than cheaper and inferior galvanised steel tubing when in contact with soil. And it’s incredibly strong. It will literally be as good as new for decades. Which is why we only use PolyTube for the polytunnel frames in our kits.

Subscribe to our newsletter for exclusive offers and discounts

Polytunnel door frames

Our metal frames are super-strong and so is the timber we use for our door kits. We only use the best quality tanalised timber. Tanalised timber means the wood has been treated with preservative which is applied using high-vacuum pressure.

Because it is applied using very high pressure the preservative works its way right into the very core of the timber. This makes it far more longer-lasting than ‘normal’ treated timber in which preservative is only applied to the surface.

Tanalised timber is weather resistant and protected against decay and insect attack. This makes it ideal for the UK climate and is why it’s the obvious choice for us to use for the door frames in our polytunnel kits.

The polythene cover

Polythene is polythene. Right? Well, not really. A poor quality polytunnel cover will split easily in adverse weather. It’s unlikely to last more than a few months.

However, we use a commercial grade polythene cover which is guaranteed for five years but which we confidently expect to last at least eight years. The cover we use is the XL Horticulture SunMaster Diffused. It’s a bit of a mouthful but is super hardwearing, has anti-drip and anti-fog properties and has 60% diffusion which makes it perfect for UK conditions.

This cover is the one we use on our own polytunnels in our five-acre nursery because we know we’ll always get great results and it’ll last for years.

Click here to see our range of commercial grade polytunnels ranging from 10x12’ for the home gardener or allotment holder to 18x90’ for commercial growers.

If you need any further information don’t hesitate to contact us.